Porosity Reduction in Aluminium Deposits Produced via Arc DED using Hot Wire TIG (H-TIG) and Argon Purging

TWI Industrial Member Report 1189-2024 [pdf / 1,091KB]

By Karan Derekar

MWeldI

Industrial Need

Aluminium and titanium alloys are widely used in aerospace and automobile sectors for their light weight and corrosion resistance properties whilst titanium also provides a high strength to weight ratio and high temperature properties. However, both alloys suffer from porosity formation during arc-directed energy deposition (DED) and when welding deposits prepared using additive methods. The technique of hot wire TIG is applied for welding of stainless steels and high strength steels. However, the suitability of hot wire TIG for arc-DED to deposit aluminium and titanium has been investigated to a much lesser extent. The project seeks to address the issue of porosity formation in aluminium and titanium DED deposits.

Key Findings

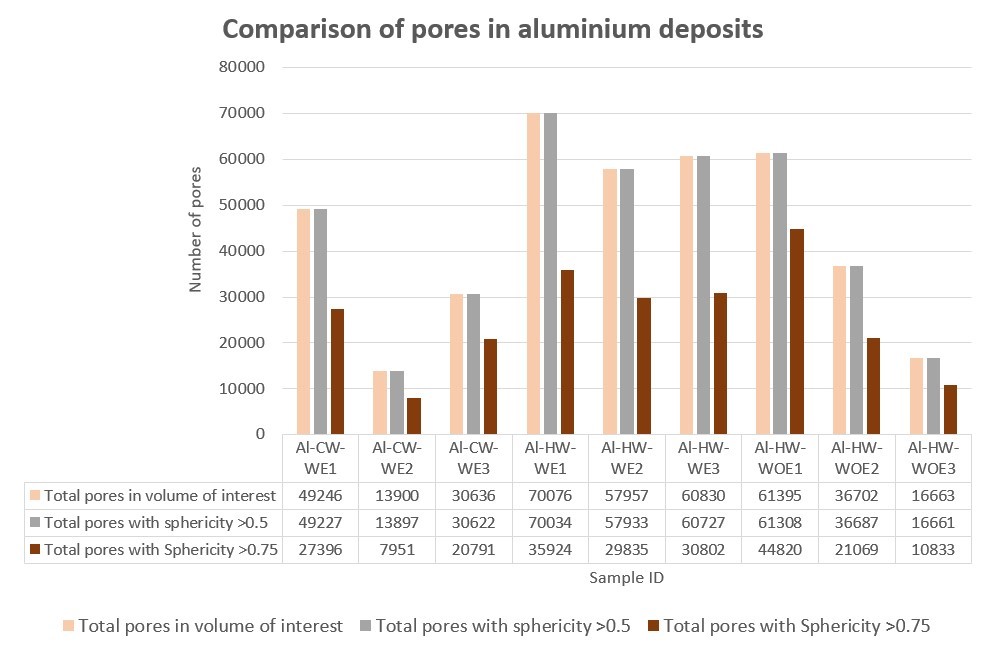

- Arc DED deposits were prepared using hot wire TIG technique using an argon (Ar) shielding enclosure. Pores with volume lower than 0.01mm3 were predominantly present (>99% of all pores).

- It was found that aluminium deposits manufactured using hot wire and enclosure showed more pores than without enclosure condition and cold wire condition. This further needs additional testing to identify potential reasons.

- CT scanning of titanium alloy deposits for the given thickness showed limitations.

Impact

The planned experimentation and testing were completed. In literature, porosity with volume up to 0.3mm3 was reported, however, in this project pores with size lower than 0.01mm3 were predominantly present. Therefore, overall porosity size reduction was achieved in this project by development of base parameters.

An insight was provided on the concept of using hot wire TIG for the manufacture of arc DED deposits. Whilst the project focused on this concept showing an impact of hot wire deposition on porosity formation and distribution, however, no significant improvement was achieved. It is proposed that the use of an enclosure during deposition trials may have had a detrimental effect, however, further investigation is recommended to better understand and develop the process in the near future.

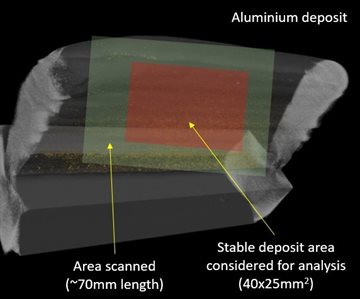

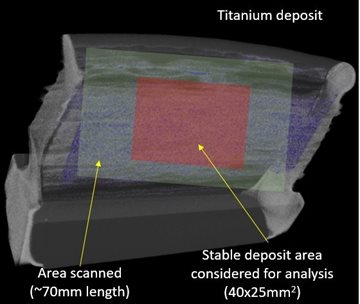

Representative CT scans of deposits in (a) aluminium and (b) titanium.

Graphical comparison of total number of pores in aluminium deposits