Development of Novel Ultrasonic Inspection Capability for Sizing of Rough Cracks

TWI Industrial Member Report 1191-2024 [pdf / 1.601KB]

By Miles Weston and Mark Sutcliffe

Industrial Need

Accurate detection, sizing and characterisation of in-service crack-like flaws on safety critical industrial assets are of key importance to industry. Increasing the accuracy with which crack-like flaws can be detected, sized and characterised, allows for improved fitness-for-service assessments, resulting in improved safety and reduced cost for industry.

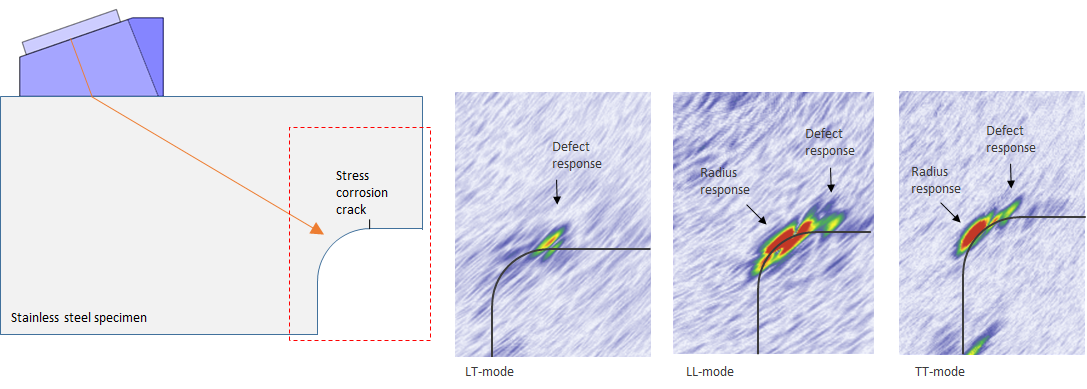

A number of novel ultrasonic testing inspection features are presented and their benefits and shortfalls for detection and sizing of rough crack flaws are demonstrated. This includes the pulse-echo longitudinal-transverse wave mode (LT mode), which enables suppression of some common geometric reflectors, enabling improved detection of crack-like flaws otherwise masked by such reflectors. The benefits of phase coherence algorithms are also investigated to assess their ability to enhance crack tip and crack facet responses to improve their detectability to support accurate flaw sizing and characterisation.

It is envisaged that the new FMC-TFM inspection approaches described in this report may be used by TWI Member organisations to extend the number of assets applicable to ultrasonic testing as well as to improve rough crack flaw detection and sizing accuracy.

Key Findings

- FMC-TFM pulse-echo LT-mode inspection can successfully supress signals from geometric reflectors e.g. backwall, relative to a crack corner trap response, increasing the likelihood of detecting a corner trap or crack tip/end facet when in close proximity to a geometric reflector.

- FMC-TFM pulse-echo LT-mode inspection has been shown to achieve similar levels of SNR to industry standard pulse-echo techniques and could be considered for industrial applications where the benefit of using the technique is identified.

- Due to the transverse wave leg of LT-mode, the technique is generally not suitable for inspection through coarse-grained weld metal. This is aligned with industry best practice, which typically limits ultrasonic inspection of coarse-grained materials to longitudinal wave transducers.

- FMC-TFM was shown to offer greater SNR than the phase coherence technique for both the corner trap and tip/facet response of a fatigue crack, however the phase coherence technique was still capable of detecting corner trap and tip/facet responses with good SNR.

Impact

The research and developments made within this work broaden the capability of ultrasonic testing for inspection of crack-like defects. Both LT mode and phase coherence algorithms have been tested on components containing realistic rough crack flaws and are ready for industrial trials.

Inspection of stainless steel specimen containing a stress corrosion crack (SCC), which was surface breaking adjacent to a back wall containing a radius of curvature. SCC inspected using FMC-TFM LT-mode, LL-mode and TT-mode.