Fatigue Performance of Carbon Steels in the Presence of Corrosion Pits

TWI Industrial Member Report 1185-2024 [pdf / 8,078KB]

By Dr. Carol Johnston Emre Akgun and Eduardo Hippert

Industrial Need

Corrosion pits can act as preferential locations for fatigue crack initiation for materials subject to harsh environmental conditions, which is a particular concern for steel support structures of offshore wind turbines. There are many academic studies of the pit-to-crack transition but the conditions for such a transition from a corrosion pit to a fatigue crack are not widely understood by industry. Assessment of corroded components and structures for continued service is therefore a challenging task. This report describes a programme of fatigue tests on specimens extracted from material that had been in operation, offshore, for more than 15 years and so had realistic pre-corroded surfaces. It aimed to demonstrate the effect of the presence of corrosion pits on the fatigue endurance of carbon steel welds. After characterisation of the pits that initiated the fatigue cracks, a fracture mechanics approach is applied, to link pit size with resulting fatigue life.

Key Findings

- The fatigue performance of specimens with pre-corroded surfaces showed performance in line with the relevant BS 7608 seawater S-N curves.

- The presence of the pre-corroded surfaces, even for specimens tested in air, caused the results to be comparable to the seawater versions of the standard S-N curves. In spite of the pre-corroded surfaces, the tests on the brace material in seawater produced fatigue lives that were a factor of 3.2 below that of the specimens tested in air, which is in line with the factor of three difference between the free corrosion and air curves in BS 7608.

- The projected pit area was used to calculate DK using the Murakami and Endo equation. The pit dimensions were also used calculate DK assuming the pits were semi-elliptical cracks. The fatigue lives calculated using fracture mechanics with these DK values were all lower than the measured lives.

- This is likely to be because the fracture mechanics calculation assumes that crack growth begins immediately. The number of cycles needed for the crack to initiate from the corrosion pit were not captured in the fracture mechanics analysis.

Impact

The results of this study give industry confidence in the seawater S-N curves in the current fatigue design document, BS 7608. The fatigue life of specimens with significantly corroded surfaces were well represented by the seawater versions of the S-N curves.

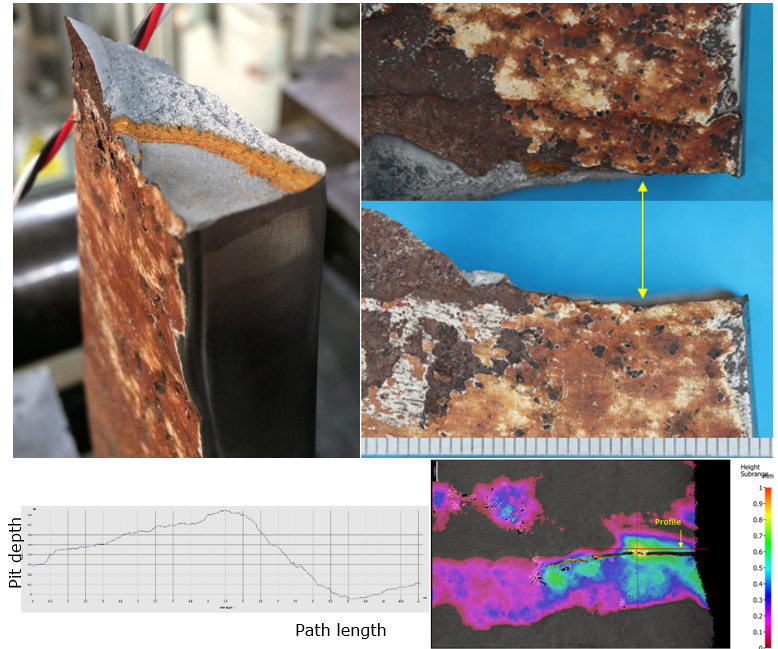

From top left, fracture faces of a specimen extracted from a corroded brace after testing in air. Map of the corroded surface. Line profile from the map showing the geometry

From top left, fracture faces of a specimen extracted from a corroded brace after testing in air. Map of the corroded surface. Line profile from the map showing the geometry