Thu, 20 March, 2025

We were delighted to invite around 55 attendees to our in-person seminar, ‘Opportunities and Challenges with Cold Spray in Industry,’ at our headquarters near Cambridge, UK, on 18 March, 2025.

The workshop was created to facilitate discussions around the challenges and opportunities in the advancement of Cold Spray as a pioneering, sustainable and innovative technology for material repair, surface enhancement/functionalisation, and additive manufacture.

The event, funded by the UKAEA welcomed representatives from academia and business, including powder manufacturers and equipment suppliers from across the cold spray supply chain. They were joined by industry leaders drawn from sectors including aerospace, defence, space, and nuclear.

About Cold Spray

Cold spray technology stands out due to its solid state nature, low heat input, versatility, efficiency, cost effectiveness, and ability to work with sensitive materials. These advantages make it a powerful tool for applications ranging from radiation shielding in nuclear reactors, to the repair of aerospace components, and additive manufacture.

This versatility has given cold spray broad appeal across multiple industry sectors, where it has traditionally been used for the application of coatings, the repair of damaged components in non-load bearing applications, and for the additive manufacture of parts to a near net shape.

However, there have been a number of factors that have prevented the more widespread adoption of the technology, including techno-economic and regulatory issues and a general lack of awareness around cold spray.

Despite this, the cold spray market has seen continuous growth over the past few decades, and is now predicted to increase in market value to $1.6B market by 2030. In order to fully unlock this potential for industries including the aerospace, automotive, defence, and utility sectors, a collaborative effort is required. This will allow for the development of new materials, the optimisation of process parameters, a more streamlined regulatory process, and the creation of industry standards and best practice.

Opportunities and Challenges with Cold Spray in Industry

The event itself was opened with a welcome address from John Hill, TWI’s Director of Technology and Strategy, TWI, before the start of the first session, which was chaired by TWI’s Ben Robinson.

The first session began with a section dedicated to the ‘UKAEA Fusion Industry Programme- Phase II,’ and containing three presentations:

- Keynote talk from UKAEA (Miguel-Zavala Arredondo, UKAEA)

- Cold Spray Additive Manufacture of Materials for Plasma Facing Fusion Applications (Phil McNutt, TWI)

- Cold Spray Additive Manufacturing of Oxide Dispersion Strengthened Alloys (Dibakor Boruah, TWI)

This was followed by a second suite of presentations focussed on, ‘Cold Spray Application Cross Industry Sections:’

- The Potential of Cold Spray in the Nuclear Sector: Examples from Fusion and Gen IV Fission (Jan Cizek, Institute of plasma physics of the Czech Academy of Sciences)

- Cold Spray Propellant Tank Development for Cubesat Ion Propulsion System (Neil Wallace, The European Space Agency)

- The Tokamak Energy Approach to Fusion Material Challenges (Jim Pickles, Tokamak Energy)

- Applications and Challenges with Cold Spray (Phil McNutt, TWI)

A third group of presentations closed the first session, detailing, ‘Cold Spray Supply Chain Developments:’

- Powder Characteristics Required to Meet the Challenges for Widespread Adoption of Cold Spray Additive Manufacturing (CSAM) (Gordon Kerr, Metal Powder Emergence (MPE) Ltd)

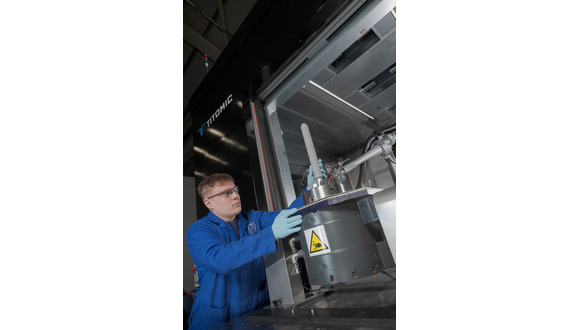

- Equipment Manufacturer Presentation (Klaas Rozema, Titomic)

Following lunch at our premises, the second session of the event began, comprising tours and demonstrations in the TWI laboratories.

The third and final session of the day was exclusively for TWI Industrial Members and featured an insight into ‘TWI Cold Spray Strategy’ courtesy of TWI’s Ben Robinson ahead of final comments and the event’s close.

Cold Spray at TWI

TWI has been at the forefront of cold spray R&D for over two decades, having delivered 60+ projects for our Industrial Members across various industrial sectors, as well as leading government programmes into the technology.

As a leader in the technology, we offer technical expertise across all industry sectors and cold spray applications, supported by world-class, in-house facilities (Titomic-523, Impact-5/11, TKF-1000 systems).

Email us at contactus@twi.co.uk to find out more, and download our ‘Cold Spray Technology Centre Brochure,’ below:

TWI Cold Spray Technology Centre Brochure - pdf - 4mb

This project has been supported by UK Atomic Energy Authority through the Fusion Industry Programme. The Fusion Industry Programme is stimulating the growth of the UK fusion ecosystem and preparing it for future global fusion powerplant market. More information about the Fusion Industry Programme can be found online: https://ccfe.ukaea.uk/programmes/fusion-industry-programme/