Tue, 02 July, 2024

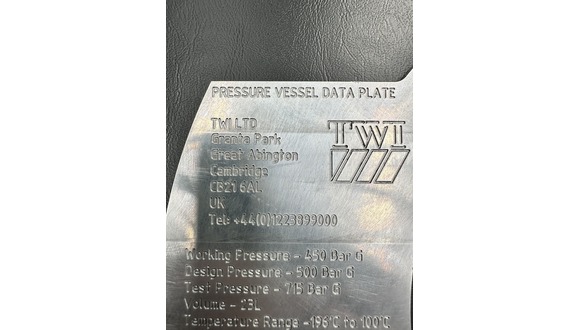

A team from TWI has been working on the design and manufacture of two custom-made 450 bar hydrogen pressure vessels that should soon be ready for use.

The hydrogen vessels recently passed their hydrostatic tests and have now been externally verified as being ‘designed, manufactured and tested’ in accordance with design standard PD5500:2021+A2:2022 Category 1 and Pressure Equipment Directive.

Due to the size of the pressure vessels, we engaged LRQA as a notified body for the certification which, now complete, means we can continue with the build and look forward to commissioning.

Once built, the vessels will be integrated into a custom-made mechanical frame that will allow for the testing of both metallic and polymeric specimens with a load capacity of 100kN fatigue and 200kN static.

Safety is of paramount importance, given that the system will include large amounts of stored energy and gaseous hydrogen within the pressure vessels. At max pressure this would amount to over 10,000 litres of hydrogen gas, which actually equates to over 250,000 litres once the flammability range of hydrogen is taken into consideration.

As such, the testing system has been designed to be ATEX, DSEAR, and Functional Safety (SIL) compliant. In practice, this meant engineering safety problems out during the design stage, using multiple redundant systems to remove common failure points, the use of nitrogen as a means to remove oxygen and prevent the formation of a flammable atmosphere, and the addition of specialist containment systems.

Once completed and commissioned for use, the system will allow for a range of tests, including tensile, slow strain rate tests, fatigue endurance, fatigue crack growth, fracture toughness, compact tension, single edge notch bend, and single edge notch tension testing. In addition, future methodologies have been included during the design stage with features that will allow for low cycle fatigue testing with some additional development. Further, the large internal volume of the pressure vessels allows for them utilised in an exposure or ageing function.

The creation of pressure vessels and a testing frame of such a size is a first for TWI and testament to the engineers, experts and technicians involved.

We will bring you more information as the system build continues and let you know once it is ready for use by our Industrial Members but, if you have any questions, please contact us by using the email address, below...