Tue, 05 November, 2024

From 2021 to 2024, TWI’s friction stir welding (FSW) team took part in the EU-sponsored RESURGAM project.

The project, which was conducted on behalf of the EU shipbuilding industry, investigated the feasibility of developing the friction stir welding of steel for two specific applications:

- The manufacture of new ships using a block building technique that makes use of FSW’s high strength and low distortion capabilities

- The underwater repair of damaged hulls to enable ships to be repaired without the need for dry docking

TWI successfully developed the underpinning steel FSW technology required for the project, allowing the other project partners to meet both the stated goals of the project.

In addition to the original targets of the project, TWI achieved further breakthroughs, enhancing steel friction stir welding in areas that will prove suitable not just for shipbuilding, but for other industry sectors including energy, oil and gas, civil engineering and defence too.

Table 1. Targeted and actual achievements for steel FSW in RESURGAM

|

Aims and Objectives

|

Target

|

Achievement

|

|

Steel grades welded

|

S355 and S460

|

Carbon steels S355, S460, S690, DH36

Stainless steels 304, 316

|

|

Steel thicknesses welded

|

6mm and 12mm

|

3mm, 6mm, 8mm, 12mm, 15mm, 25mm

|

|

Tool life

|

30m in 6mm S355

|

60m in 6mm S355

30m in 12mm S355

|

|

Welding environment

|

In air, underwater

|

In air, underwater, under oil

|

|

New FSW techniques for steel

|

(Stretch goal - not originally planned)

|

• SDS-FSW demonstrated in 25mm thick steel

• SS-FSW system under development (would potentially allow fillet welding)

• Data gathered from thermal studies suggests CoreFlow and Hybrid SAW/FSW may be possible

|

|

Novel backing bar system devised

|

(Stretch goal - not originally planned)

|

Moving backing bar developed, which will enable higher quality welding on curved surfaces and inside tubulars

|

|

Fully forged integrally stiffened panel developed

|

(Stretch goal - not originally planned)

|

Panel reduces number of welds required by 50%

|

Key technical findings from the steel FSW development programme include:

- Many different grades of steel can be friction stir welded, including the welding of dissimilar grades to each other

- Welds made underwater do not seem to be adversely affected by the presence of the water

- The FSW of steel produces complex, fine grained microstructures that can have excellent properties – strength, toughness and fatigue resistance – which can at least equal and often exceed those of the original parent metal

- Friction stir welded steel has good tolerance to the presence of defects, which are identifiable by standard NDT techniques

- Fatigue properties seem to be dominated by the surface quality of the weld more than by any internal defects that are present

An interesting further finding of the project, which was made during visits to several shipyards, was that it appears that existing submerged arc welding (SAW) equipment widely used in modern yards could potentially be adapted to perform FSW, thus reducing the barrier to market posed by the need to purchase FSW machines.

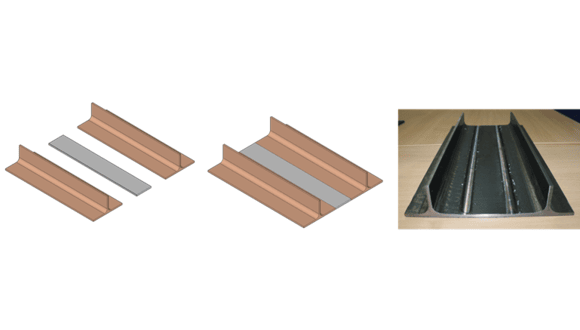

In addition, if FSW were to be implemented using existing SAW gantries, it might be possible to combine SAW and FSW in a hybrid system, making use of the benefits of both systems and delivering a better overall system at relative little extra cost. Such a system might then be employed to manufacture stiffened panels using a technique investigated in the RESURGAM project, replacing the traditional process of arc welding stiffening ribs to plates of steel by a process to butt weld rolled T sections and spacer plates, creating a stronger, fully forged panel with less distortion and only half the number of welds (see figure 1, below).

Figure 1. Novel technique developed for the manufacture of stiffened panels by friction stir welding that allows complex stiffened panels to be manufactured whilst reducing the number of welds required by half when compared to the existing arc welding technique.

Figure 1. Novel technique developed for the manufacture of stiffened panels by friction stir welding that allows complex stiffened panels to be manufactured whilst reducing the number of welds required by half when compared to the existing arc welding technique.

For further information on both the RESURGAM project and TWI’s friction stir welding capabilities, including opportunities to join forthcoming Joint Industry Projects, please email contactus@twi.co.uk.

Project RESURGAM received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101007005