Fri, 29 January, 2021

Are You Suffering Problems With Sigma Phase Embrittlement of Super Duplex Stainless Steels?

Sigma is a deleterious phase which can form in stainless steels, and their weldments, subjected to incorrect or uncontrolled heat treatments and/or production and fabrication processes. Superduplex stainless steels, particularly those richer in Cr and Mo, such as UNS S32750 or S32760, can be sensitive to sigma phase embrittlement due to the complex thermomechanical processing required to achieve the corrosion resistance and mechanical properties of these grades. Sigmatised materials are a significant problem in industry as they have reduced toughness and corrosion resistance compared to expected parent material properties.

Embrittlement by sigma phase can be avoided by using robust material specifications. However, in some cases sigma phase, and associated cracking and corrosion, have been found in materials compliant with industry standards, such as ASTM A790/A790M.

TWI has a track record in supporting clients’ identifying and quantifying sigma phase in stainless steels, using a wide range of conventional and advanced characterisation techniques, and evaluating mechanical and corrosion properties with Standard and bespoke tests, including ISO 17781 and ASTM A923, etc. We offer clients authoritative advice assessing test results against specifications and our industry experience. We can advise on appropriate remedial and mitigation actions, including onsite NDT, heat treatments, engineering critical analyses, and repair or replacement of affected components for a range of industries, including oil and gas.

Please contact us for help with sigma phase, or any other issues with stainless steel and corrosion resistant alloys and their weldments.

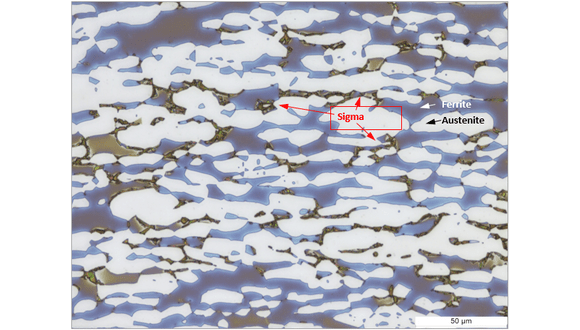

Figure 1. Light micrograph of duplex stainless steel etched in a 20% NaOH solution. Sigma phase appears as the darkest phase, mostly adjacent to the interphase boundaries as marked with red arrows

Figure 1. Light micrograph of duplex stainless steel etched in a 20% NaOH solution. Sigma phase appears as the darkest phase, mostly adjacent to the interphase boundaries as marked with red arrows