Thu, 27 March, 2025

A new research paper has been published on the topic of the ‘Application of machine learning in additive manufacturing of a novel Al alloy heat exchanger.’

The research paper, published in The International Journal of Advanced Manufacturing Technology, was written by National Structural Integrity Research Centre (NSIRC) and University of Birmingham PhD student Francesco Careri, who is being mentored by TWI’s Technology Consultant for Thermal Processing Technologies, Dr Raja Khan PhD CEng FWeldI FIMMM.

Additive manufacturing of complex geometries has faced limitations with regard to the dimensional and geometrical accuracy that is obtainable, especially when the geometries require thin features such as those designed to tailor the mechanical and thermal properties of novel heat exchangers (HXs).

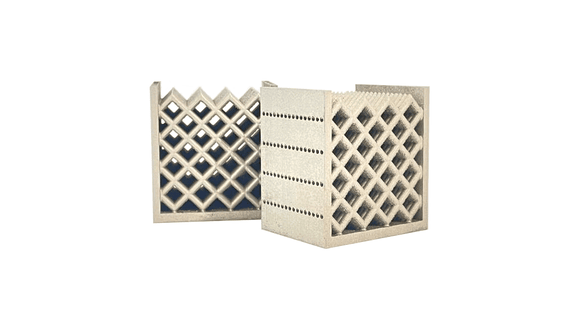

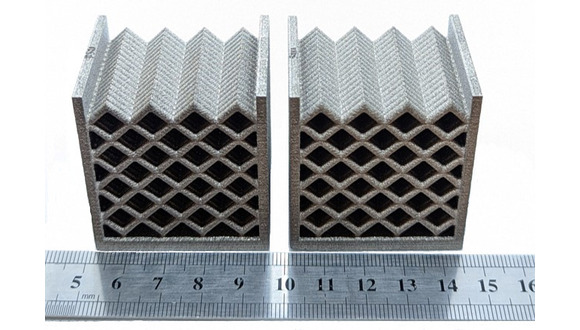

This paper details the fabrication of a novel, complex, thin hollow-walled lattice compact HX using the Powder Bed Fusion-Laser Beam on Metal (PBF-LB/M) process, with the use of machine learning to optimise the workflow and ensure alignment between the process parameters and HX design.

A process map for the A205 aluminium alloy to be used was generated to investigate metallurgical defects and surface quality before optimal process parameters for defect-free materials were estimated using a neural network (NN). Further, optimisation evaluated the influence of laser parameters, beam compensation (BC), and contour distance (CD) on the geometrical and dimensional accuracy of thin features, with a second NN predicting optimal BC and CD.

The optimisation reduced the thickness deviations in the hollow lattices to under 2% so a prototype of the novel HX could fabricated and characterised to evaluate manufacturing feasibility. Following fabrication, the HX underwent SEM analysis to search for pores that could potentially lead to leakage or part failure.

This paper outlines how PBF-LB/M can be guided by machine learning-based optimisation to manufacture manufacturing highly complex, thin-walled HX designs, although performance could be further optimised through new machine learning models that could allow for recalibration and re-optimisation to match changes to material properties, geometry, and manufacturing settings.

This paper, which was co-authored with Dr Leonardo Stella and Professor Moataz Attallah of the University of Birmingham, shows how TWI is not only supporting new research for industry but also helping to develop the next generation of industry experts.

You can read the paper in full, here.