Tue, 25 March, 2025

We are holding our in-person Technology Fellows’ Day on 15 May, 2025, bringing together the world-leading expertise of our Technology Fellows to focus on challenges and solutions for nuclear and fusion with crossover to other industries.

Each of these highly-regarded Technology Fellows are experts in their field, having made a genuine difference through their knowledge and leadership. Among the Fellows due to speak on the day is Dr Isabel Hadley CEng, Eur Ing, FWeldI, our Technology Fellow for Materials and Structural Integrity.

Dr Isabel Hadley

Dr Isabel Hadley

Dr Hadley’s presentation on the day will investigate, ‘Defect assessment in high-integrity pressure equipment: from qualitative to quantitative.’

The use of defect assessment procedures such as R6 and BS 7910 to assess known or hypothetical flaws in high-integrity welded structures is well-established, with both procedures having been under continuous development since the 1970s. Both of the techniques use the concept of a Failure Assessment Line (FAL), which can be regarded as a ‘failure surface,’ dividing safe from potentially unsafe conditions.

However, a limitation of both R6 and BS 7910 assessments is that they do not define the probability of failure, so there is a tendency to make all inputs (applied and residual stresses, flaw size, fracture toughness, tensile properties) conservative, so that the overall results are safe (but unquantified).

An alternative approach is to use Probabilistic Fracture Mechanics, where each input is defined in terms of a probability distribution, and millions of individual calculations are carried out, comparing each answer with the definition of the FAL, from which the probability of failure (POF) can then be calculated directly, albeit approximately.

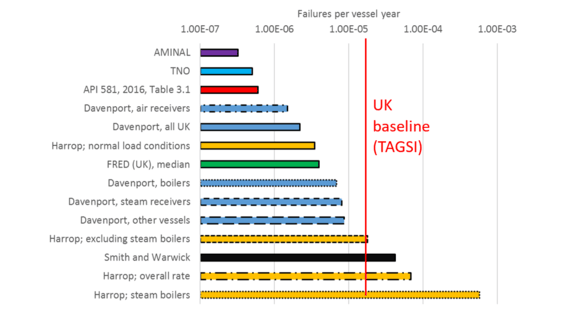

How do we know that the answer is credible? One answer is to ‘calibrate’ the calculations against the results of large-scale laboratory tests containing artificial flaws, for which the inputs are well-defined; where specimens have failed (for example, by brittle fracture), the POF is by definition close to 1. The next step is to postulate actual flaw distributions in a similar structure (taking into account the effects of inspection) and repeat the calculations, this time applying the stresses that the structure will experience under design and/or accident conditions. Finally, we can compare the results with those of industry-wide surveys, e.g. the number of incidences of catastrophic failure in pressure vessels per vessel year.

Isabel’s presentation will include a demonstration of how the technique can be used to estimate POF in the welds of high-pressure piping, based on the results of large- and small-scale testing, and expert input from TWI’s welding and inspection engineers.

Catastrophic failure rates for pressure vessels

Catastrophic failure rates for pressure vessels

You can find out more about our Technology Fellows Day, here:

https://www.twi-global.com/media-and-events/events-diary/twi-technology-fellows-day