Tue, 03 December, 2024

TWI is one of around just five organisations anywhere in the world to have access to a ground-breaking coaxial electron beam wire additive manufacturing (AM) system from xBeam.

Available for our Industrial Members to explore, this system boasts a coaxial beam and wire feed system that not only removes many alignment issues – improving productivity and ease of set-up – but is capable of working with wires of up to 3mm in diameter, allowing for incredibly high deposition rates.

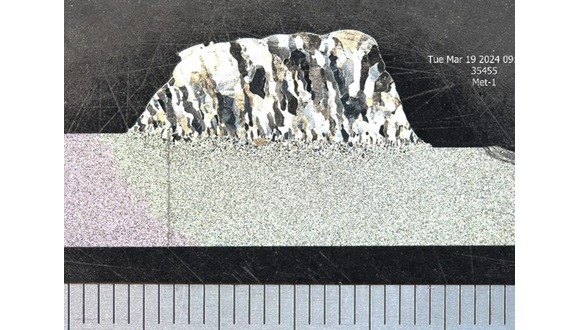

As an electron beam system, it delivers clean AM parts in a vacuum environment, laying down fine equiaxed grains that improve the mechanical performance of components. Benefits of xBeam include:

- Cost saving - decreasing production costs by minimising to removing need for post-processing.

- Improved product performance/quality – minimising rejection of manufactured parts.

About the xBeam-18/I System

The xBeam-18/I electron beam system is capable of processing 7 different wire diameters, ranging from 1.0mm up to 3.3mm (with tests into potentially larger diameter feeds too). It is mounted on a 3 x 3 x 4m chamber and is able to build metre scale components with a 1,000mm vertical axis. It also has two in-chamber video cameras, which are held in protective casings that allow for the adjustment of xGun positioning during processing.

Contact Us

We believe that this system is of interest to anyone using additive manufacturing, especially in high-value industries such as nuclear, fusion, aerospace and space.

Our team is ready to talk to you about the benefits and capabilities of this innovative system, including the increased deposition speed and quality and reduced costs it offers.

You can see more by watching the video, below, and contact us by emailing contactus@twi.co.uk to find out more.