Mon, 07 February, 2022

TWI is working alongside Pinweld to deliver innovative solutions for fast and repeatable plastic pipe joining and repair.

Background

It is reported that world demand for plastic pipes (PVC, PE, PP, ABS) is projected to rise >5% per annum to over 20 billion metres. A clear growth market, plastic pipes and ducting systems are used for a variety of applications, from chemical plants to lining metal pipes in the oil and gas industry and transporting water and gas in the utilities sector.

As good as this growth has proved to be, it has been limited by the challenges and potential negative impacts the existing joining methods have had on project economics. There are also long-term challenges associated with reducing leakage and the UK water industry has committed to reduce leaks by 50% by 2050. A key challenge is to achieve ‘leak free’ networks or at the very least, ultra-low losses. In addition, and targets aside, leaks (the majority of which occur at the joint) can cause significant environmental damage and prove costly, with the UK alone reporting over 3 billion litres of water being lost each day (according to statistics from the Consumer Council for Water).

Two of the main methods of joining plastic pipes are butt fusion and electrofusion welding. Both of these welding processes are proven to be effective but are time consuming, subject to environmental challenges, costly to implement (electrofusion fitting costs and long weld/cool times) and can result in leaking joints if not completed correctly, by trained and qualified personnel. Furthermore, installation costs associated with butt fusion and electrofusion welding have been identified as one of the limiting factors keeping some industries from fully embracing the potential of plastic pipe systems, therefore pipeline installers are constantly looking for more efficient and robust joining methods.

Pinweld and Pinweld of Plastic Pipes Project

Pinweld is a new plastic welding process that utilises a compact, lightweight, self-regulating, low-energy tool to join plastic components together. Unlike current technologies, which can involve expensive heating mechanisms and bulky equipment, the weld achieved by Pinweld uses a minimally invasive technique to precisely heat the interface of two plastic components. Pinweld was initially developed for joining flat sheets, where joint strengths close to parent material strength have been achieved for a range of plastic materials.

If adopted, Pinweld could enable fast, repeatable plastic pipe jointing or pipe repairs to be carried out, without the need for additional adhesives, solvents or fittings.

The use of Pinweld technology to enable butt welding and repair of plastic pipelines has its challenges, notably for larger diameter pipe systems, but based on the empirical evidence obtained, we believe the desired output is entirely attainable in a modest timescale. The vision is to build on the good work and solid science achieved by the existing Pinweld technology and to develop pipe-specific new controls, equipment, plus the tools and procedures for welding thermoplastic pipes of all diameters.

A feasibility project is proposed, with the aim of developing a pipe welding machine in order to produce welds with a strength at least as good as the parent material. The prototype system and pins will be used to help identify the strengths, weaknesses and potential of the technology and will be used to develop and validate Pinweld procedures for a range of plastic pipe diameters.

The project is expected to produce a number of design improvements, which will be the subject of further patents, including machine-learning and electronic control of mechanical function and will deliver key information on design iterations of the already developed Pinweld head and tools. TWI will input into the prototype design process and provide access to specialist expertise, materials and weld testing and equipment.

The business development activity will initially focus on consolidating Pinweld as a primary plastic pipe welding technology for the oil and gas and utilities industries. Other global markets with significant potential include chemical processing, nuclear, hydrogen and power. A code of practice (in consultation with industry representatives) will be developed and this may be used to inform a formal Standard for welding pipes using the Pinweld technology.

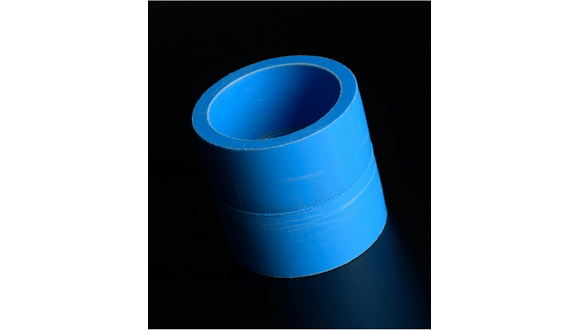

Pinweld pipe welding has been trialled on a semi-autonomous jig (a pinwelded PE pipe is shown in the photograph below). A natural development will be to harness existing robotics and non-destructive testing techniques to create a fast, integrated plastic pipe welding manufacturing process, able to build thermoplastic pipelines efficiently and with zero defects.