Thu, 28 April, 2022

In collaboration with other consortium partners from industry, TWI is working on the Innovate UK-funded e-Tau Project.

The project, which started in July 2021, will develop, test and validate a novel precision laser welding system optimised for use on large aerospace and automotive structures. e-Tau will combine a cutting-edge high precision Tau robot manipulator, advanced laser beam wobbling optics, integrated with intelligent quality assurance and control sensors.

This novel precision laser welding system will facilitate a step-change in the quality of larger aerospace and automotive welded structures, while offering an automated, fast and high-quality laser welding system with repeatable results.

It has been a challenge in the past to avoid defects in the larger, thin sheet structures required for lightweight aircraft and automobiles, as laser welding is particularly intolerant to gaps between parts and any beam-to-work positioning errors (as a result of incorrect part placement, inadequate fixturing, distortion, etc).

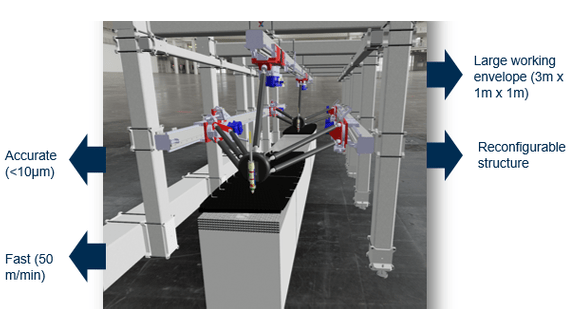

Figure 1. e-Tau System Specifications

Figure 1. e-Tau System Specifications

e-Tau seeks to solve these challenges by delivering cost-effective, flexible, and accurate beam manipulation over a large working envelope, including active adjustment of the beam’s application in real-time.

This truly innovative system will deliver laser welding of small welds across larger working volumes for industry, providing improved tolerance to part placement and fit-up, improved weld quality, and increased productivity. There will also be a reduction in costly repairs and scrap, and a greatly reduced need for expensive and time-consuming post-weld NDT.

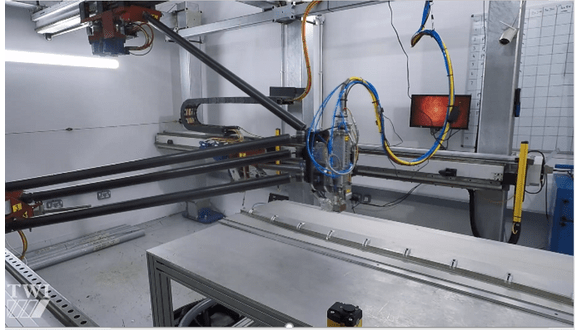

Fig 2. Tau Robot at TWI Laser Cell

Fig 2. Tau Robot at TWI Laser Cell

TWI is working alongside project coordinator Prodtex and fellow partners CAV, LOE, and Gestamp on the e-Tau Project, ensuring that e-Tau meets the needs of the aerospace and automotive industries.

The e-Tau consortium consists of the following partners:

TWI Ltd

TWI is one of Europe's largest independent RTOs, specialising in all aspects of materials joining and associated technologies. TWI is a non-profit-distributing organisation with approximately 700 industrial member companies; supporting activities on ~3,500 sites in 60 countries across all sectors manufacturing. Furthermore, TWI also has a proven track record in successfully managing and participating in projects funded both by the European Commission and the UK government. TWI has been at the forefront of the technological development of using lasers for materials processing since the mid-1960s, providing world-class support to many industries, including the automotive, shipbuilding and aerospace and nuclear sectors. TWI has a number of laser facilities, and the development of laser processing for metallic and non-metallic materials is carried out using a wide variety of laser sources operating at powers of up to 10kW.

Prodtex Ltd

Prodtex is a technology driven Development Company with a focus on streamlining processes and procedures for our clients. It operates mainly in automation and combines experience in virtual production and an understanding of industry challenges with an exciting and considered vision of the manufacturing industry's future development. Prodtex delivers solutions to manufacturing industry and has specialised in the production of tools and equipment as well as the software development and methodology around this. Prodtex are one of the key developers of the Tau Robot, they have been working with PKM robots for the last 5 years and are excited to continue development of a production solution for the robot. The company has a partnership agreement with Dassault Systèmes, and markets and sells its product portfolio DELMIA in Sweden, Norway, Denmark and the UK. Prodtex’s main focus is to streamline processes and procedures for its clients. Prodtex offer consulting services and software solutions for the automotive, aerospace and offshore industries.

CAV Advanced Technologies

CAV Systems is the leading provider of ice protection and drag reduction technology to general aviation, commercial aerospace, and defence markets worldwide. Working alongside aircraft engineers, CAV assist in the design, testing, analysis, manufacture, integration, and approval of unique technology solutions to overcome critical safety challenges and increase the efficiency of flight. The only supplier of fluid-based ice protection systems globally and the foremost supplier of laser perforated surfaces, CAV has operated as a critical technology and manufacturing partner to major commercial OEMs since 1942. Proprietary technologies include TKS® Ice Protection Systems, the preferred IPS for most new general aviation and unmanned aircraft. The CAV Systems Group of businesses incorporates CAV Ice Protection Ltd, CAV Advanced Technologies Ltd and CAV Inc. TSK, SLD, e-TKS and uLase are registered CAV brands. Its global headquarters and principal R&D, engineering, manufacturing facilities are in County Durham, UK.

Gestamp

The Gestamp group specialises in developing innovatively designed products to achieve increasingly safer and lighter vehicles, thereby reducing energy consumption and environmental impact. Autotech Engineering R&D UK Ltd, are part of the Gestamp Chassis Business Unit, which is responsible for the design, development, prototype and testing of Chassis products. This group primarily supports Volvo, Jaguar Land Rover and Ford Motor Company with the development of chassis products worldwide and we have being doing this for the past 20 years.

Laser Optical Engineering Ltd

Laser Optical Engineering Ltd (LOE) is an ISO9001 certified company, specialising in the development of innovative and bespoke laser based imaging products and services. Established in 1996 as an independent spin-out company from Loughborough University, we are a customer focused company who pride ourselves on an ability to turn theoretical ideas into commercial products which can be used in real-life situations. LOE has been involved in a wide range of development projects ranging from the EU2020 funded Radicle and the multi-agency UK based LaserSnake2 project, to smaller regional programmes focused on specific customer applications through NATEP work. This has seen us develop systems as diverse as sensors for on-axis detection of real time signals for laser welding control, laser beam shaping for nuclear decommissioning and non-destructive testing techniques for carbon composite aircraft structures.

The e-Tau project has received funding from Innovate UK under No 107303