Tue, 09 March, 2021

TWI undertook further laboratory trials at our Cambridge headquarters for the EU-funded SheaRIOS project during February and March 2021.

The project aims to improve the efficiency and safety of wind turbine blade inspection, whilst reducing the associated costs through the development of a robotic on-blade inspection solution, using shearography, to assess wind turbine blades for wear and damage.

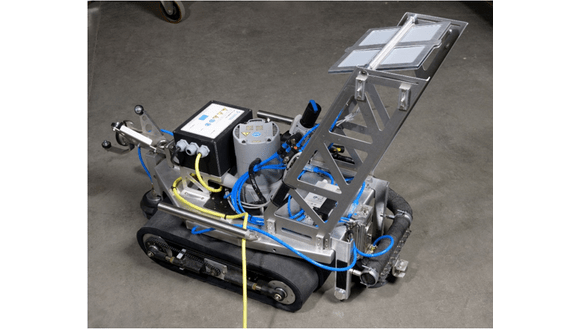

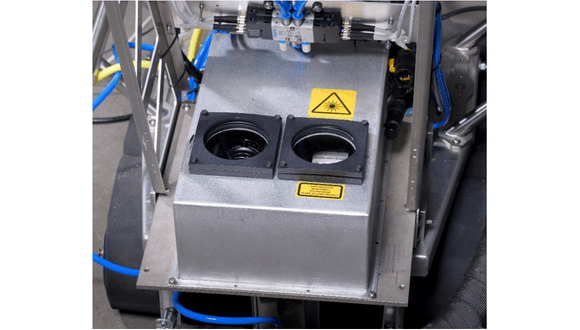

The trials involved the testing of a blade crawling robot, which was developed by project partner Dekra, and a shearographic inspection unit that was developed by TWI.

Figure 1. Blade crawling robot

Figure 1. Blade crawling robot

Figure 2. SheaRIOS inspection unit

Figure 2. SheaRIOS inspection unit

The robot and the inspection unit were deployed on a horizontal 4.5 metre wind turbine blade sample, which had artificial defects introduced beneath the surface.

Figure 3. 4.5m wind turbine blade sample

Figure 3. 4.5m wind turbine blade sample

Figure 4. Artificial defects introduced into underside of the wind turbine blade (ellipse 55x40mm; rectangle 45x35mm)

Figure 4. Artificial defects introduced into underside of the wind turbine blade (ellipse 55x40mm; rectangle 45x35mm)

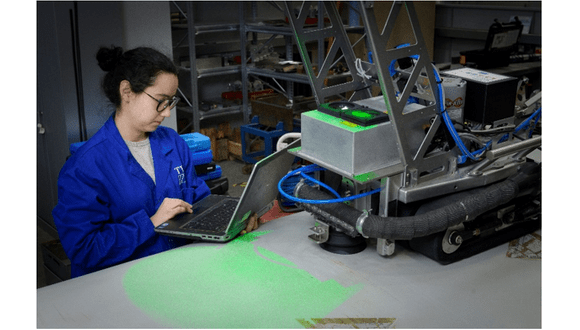

The robotic crawler moved along the blade to try to locate the subsurface defects that had been introduced.

As the crawler moved along the wind turbine blade, it used shearographic inspection to detect the artificial defects.

Figure 5, below, shows the blade crawling robot and the SheaRIOS inspection unit in use on the blade, producing a shearographic fringe pattern to show the artificial defects on-screen.

Figure 5. SheaRIOS system performing shearographic inspection on a wind turbine blade

Figure 5. SheaRIOS system performing shearographic inspection on a wind turbine blade

The successful laboratory trials show that the system is capable of performing wind turbine blade inspection tasks. On-site trials on an operational wind turbine are planned for summer 2021. You can find out more about the project here.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 780662 – H2020-ICT-2017-1