Mon, 22 June, 2020

Friction stir welding (FSW) is a solid state joining process invented by TWI in 1991. The range of components joined using FSW is continuously expanding, however this is mainly products made from aluminium alloys.

TWI has been working on the development of FSW for joining titanium alloys since 1995, and a significant breakthrough in this area came via the development of a new variant of the FSW process called Stationary Shoulder Friction Stir Welding (SS-FSW).

In 2016, TWI successfully produced a Ti-6Al-4V launch vehicle propellant tank for the European Space Agency by joining thin section parts using SS-FSW. This project demonstrated significant reductions in cost and the manufacturing cycle time when compared to the conventional manufacturing route. The details can be found through the links: Friction Stir Welded Low-Cost Titanium Propellant Tank, Pt. 1 and Friction Stir Welded Low-Cost Titanium Propellant Tank, Pt. 2.

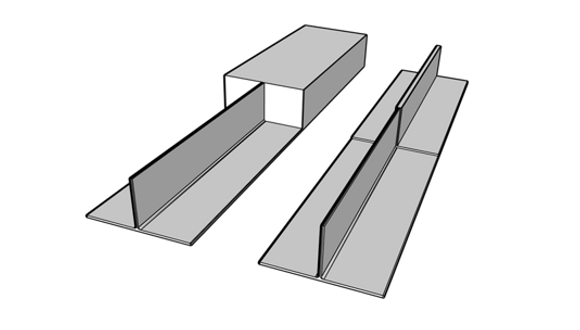

Building on this work, TWI has recently achieved another important step and successfully developed the welding process for joining two thick section (>10mm) Ti-6Al-4V plates to produce a T-joint as a near net shape technique, as shown in Figure 1. This technique saves material and reduces machining times. It is estimated that the material saving could be more than 90%, while reducing traditional machining eliminates more than two-thirds of the production costs for some components.

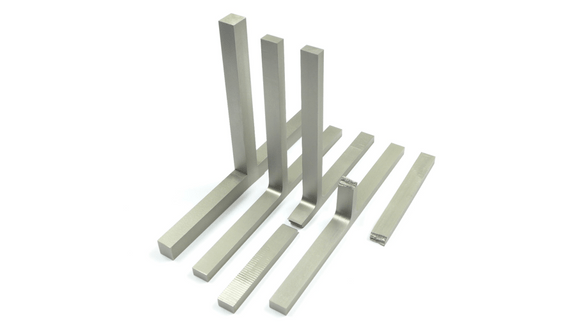

After the joint was welded using SS-FSW, specimens were extracted and assessed for tensile strength of the base and the leg plates. Both tests failed in the parent material outside the weld nugget, with ultimate tensile strengths of over 960MPa. The specimens are shown in Figure 2.

This development has significantly extended the SS-FSW capability for manufacturing critical components made from titanium alloys for aerospace and other related industries.

For further information, please contact us.

Figure 1. Illustration of titanium T-joint machined from a solid block (left) or machined from a near net shape component fabricated from base and leg plates using SS-FSW (right)

Figure 1. Illustration of titanium T-joint machined from a solid block (left) or machined from a near net shape component fabricated from base and leg plates using SS-FSW (right)

Figure 2. SS-FSW Titanium T-joint, the specimens from left to right: 1) Welded, 2) Machined to shape, 3) Tensile failure location on the base plate and 4) Tensile failure location on the leg plate, showing both failures in the parent material

Figure 2. SS-FSW Titanium T-joint, the specimens from left to right: 1) Welded, 2) Machined to shape, 3) Tensile failure location on the base plate and 4) Tensile failure location on the leg plate, showing both failures in the parent material