Numerical Modelling and Optimisation at TWI

The Numerical Modelling and Optimisation Section at TWI supports industry with a range of computational engineering capabilities from finite element analysis (FEA) and computational fluid dynamics (CFD) to data analysis and software development. TWI provides a range of bespoke electromagnetics simulation services to its Industry Members: some examples are given below.

Defect identification in circuitry

By analysing the temperature profile of current-carrying wires heated by Joule heating (the process by which the passage of electric current through a conductor produces heat), defects in circuitry can be identified. Algorithms, such as machine-learning, can then be incorporated into quality assurance procedures as part of circuit board manufacture to identify defects from the thermal profile of a circuit board.

Modelling electrostatics

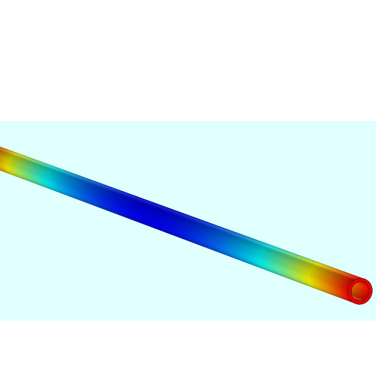

Electromagnetic models have been utilised to quantify the risk of using non-conductive pipes for gaseous hydrocarbon transport by simulating the electrostatic charge accumulation on non-conductive pipes due to water droplet and sand particle impact for Saudi Aramco. Quantification of the risk ensures that the level of charge does not build to such a level as to break-down the pipe wall, causing pin-holes to evolve (Figure 2). This work was presented at the NAFEMS World Congress and will be published in the upcoming edition of “Oil and Gas Pipelines” by Winston Revie.

For more information, contact nmo@twi.co.uk

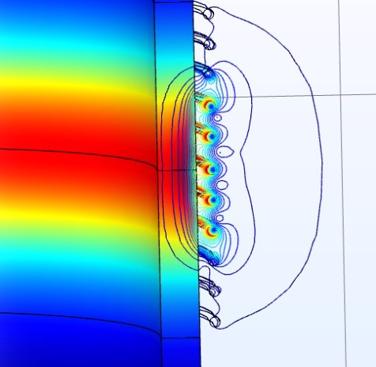

Figure 1 Simulation of electromagnetic induction post weld heat treatment.

Figure 1 Simulation of electromagnetic induction post weld heat treatment.

Figure 2 Electric potential built-up on a non-conductive pipe due to the motion of gas and sand particles.

Figure 2 Electric potential built-up on a non-conductive pipe due to the motion of gas and sand particles.