Fri, 24 January, 2025

Automated Ultrasonic Testing (AUT) has transformed the field of weld inspection, offering industries a reliable, efficient, and precise solution for ensuring the integrity of critical components. With its ability to provide high-quality data and streamline inspection processes, AUT has become a cornerstone of non-destructive testing (NDT) in sectors like oil and gas, power generation, construction, and manufacturing. For instance, AUT has significantly reduced pipeline inspection time in the oil and gas industry, improving safety and efficiency.

What is Automated Ultrasonic Testing (AUT)?

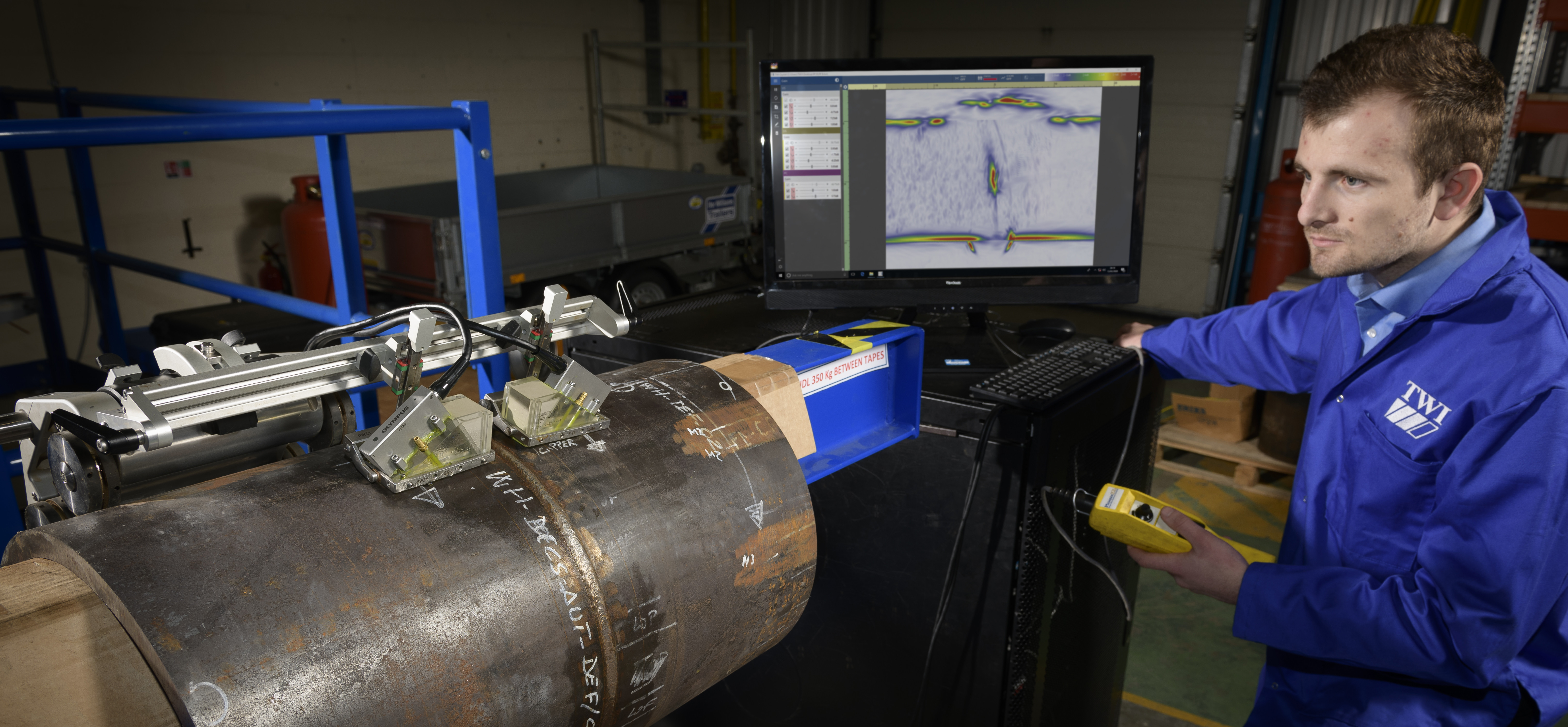

AUT is a non-destructive testing method that uses ultrasonic waves to evaluate the condition of materials and detect defects in welds. Unlike manual ultrasonic testing (UT), AUT systems use advanced technology and automated scanners to perform inspections with greater speed, accuracy, and consistency. This method is particularly effective for inspecting large volumes of welds, such as those found in pipelines, pressure vessels, and structural components. AUT also reduces the reliance on operator skill, ensuring more consistent results across inspections.

How Does AUT Work?

Setup and Calibration:

The system is calibrated using reference standards to ensure accurate results, considering material type, weld geometry, and inspection requirements. Calibration tools, such as step wedges and calibration blocks, play a crucial role in achieving precision.

Data Collection:

Ultrasonic waves are sent into the material using automated scanners, which move along the weld’s surface. These scanners are equipped with phased array probes or time-of-flight diffraction (TOFD) devices to collect data.

Data Analysis:

Specialised software processes the ultrasonic signals to create high-resolution images and detailed reports. Advanced software and its tools, such as cursors, are ease defect sizing, improving the preparation speed and accuracy of reports.

Reporting:

Results are documented in standardised formats, such as ISO 9712 or ASME BPVC requirements, ensuring compliance with industry regulations. The software has the ability to take the report format and after data analysis it automatically prepare the final report. These reports often include 3D visualizations of weld integrity.

Key Features of AUT

- Advanced Technology: Incorporates phased array and TOFD techniques for high-resolution imaging and precise defect characterisation.

- Automated Scanning: Ensures consistent data collection across extensive or complex welds, reducing human error.

- Real-Time Analysis: Provides instant feedback, allowing on-the-spot decision-making and corrective actions during inspections.

- Comprehensive Data Storage: Maintains detailed records for traceability and long-term quality assurance.

Advantages of AUT

- High Accuracy: Detects even the smallest defects, such as micro-cracks and inclusions, with high probability of detection rates in most applications.

- Efficiency: Reduces inspection time significantly compared to manual UT, boosting productivity.

- Non-Invasive: Preserves the integrity of inspected materials by eliminating the need for surface alterations.

- Safety: Eliminates risks associated with radiographic testing, such as radiation exposure, and allows for remote operation in hazardous environments.

- Cost-Effective: Prevents costly repairs and downtime by identifying defects early.

- Adaptability: Suited for diverse applications, including offshore platforms, aerospace components, and nuclear power plants, making it versatile across industries.

AUT Certification and Training

To operate AUT systems and interpret data, professionals must undergo specialised training and certification. At TWI Middle East, our AUT course equips inspectors with the knowledge and skills to:

- Interpret phased array data.

- Differentiate between defects and geometric features.

- Audit calibration and inspection records.

- Meet the requirements of BS EN ISO 9712 and the CSWIP

Automated Ultrasonic Testing is a game-changer in weld inspection, combining precision, efficiency, and safety to meet the demands of modern industries. By investing in AUT, companies can ensure the integrity of their assets, reduce operational risks, and comply with international standards.

If you’re ready to enhance your career in NDT, explore TWI Middle East’s AUT certification program and join the next generation of inspection professionals.

To learn more about the course visit: https://www.twi-global.com/locations/middle-east/training/ndt-middle-east/aut-data-interpretation or reach out to us at Enquiries@twime.com for further assistance.